Cuts exactly parallel and straight on two sides with a top and bottom knife.

Double Knife Guillotine

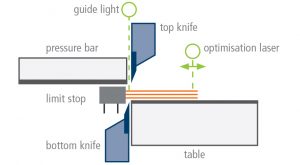

The machine cuts packs exactly parallel and straight on two sides with a top and bottom knife. Tight-jointed splicing of all types of material is possible without difficulty. The machine table with the bottom knife can be adjusted by means of a high-speed positioning drive in order to obtain the required width dimensions. After the pack is clamped in position, the top knife cuts downwards towards the table and the bottom knife cuts upwards towards the pressure bar.

IMPORTANT FEATURES AT A GLANCE

Exact Laser Guide Light

The green LED guide light clearly marks the cutting position.

Positioning control system

for diverse modes of operation and storable program operations..

Precise cutting knifes

Cuts of high quality thanks to the swinging and powerful drawing motion of the knives at an angle of approximately 20°.

Maximum safety

Occupational safety regulations met by a light barrier safety device, two-hand control, safety-orientated electric control system and mesh guards.

IMPORTANT FEATURES AT A GLANCE

- Cuts of high quality thanks to the swinging and powerful drawing motion of the knives at an angle of approximately 20°.

- Telescreen positioning control system for diverse modes of operation and storable program operations.

- An adjustable optimization laser reduces the amount of scrap.

- Simultaneous cutting by the top and bottom knife results in fast production cycles.

- The machine has a cutting capacity of approximately 2 to 3 packs per minute. This includes inserting, aligning, cutting and removing the material.

- Precise and permanent parallel guidance of the pressure bar and table.

- Rugged design of all machine components. The high pressing and cutting forces are reliably absorbed.

- The top knife,bottom knife and protective coverings are of identical size and can be interchanged.

- Good knife economy thanks to a grinding allowance of 30 mm.

- Intermittent operation of all the drives results in a low energy requirement and a low level of noise.

- Occupational safety regulations are met by a light barrier safety device, electric safety control system and swivelling protective gratings.

CUTTING VENEER

The pack is placed on the machine table and up against the limit stop. The rear cutting line is clearly marked by a guide light and the front cutting line by an adjustable optimization laser. Hence the cutting lines of the two knives and the resulting veneer waste are visible. Once the cutting width is selected, the cutting cycle is executed automatically: The table moves into cutting position, the pressure bar clamps the veneer pack in place, the top and bottom knife cut both sides ready for jointing, and the table returns to the alignment position.Pre-cutting and finish-cutting are possible for high-stress veneer.Veneer strips are cut only with the top knife in incremental mode.

NEW! Rough cut + finishing cut = Super veneer joints. No break-outs from the bottom of the veneer sheets. Tighter joints with all types of veneer.

TECHNICAL DATA

TECHNICAL DATA MultiCut DC 2800

| Type | MultiCut DC 2800 |

| Cutting length | 2810 mm |

| Insertion height | 80 mm |

| Cutting range | 20-470 mm |

| Machine table | positioning drive, 2 ball-screw-assembly |

| Pressure bar | 3 hydraulic cylinders, 2 pressure stages |

| Top knife | brake motor, gearing, crank drive |

| Bottom knife | 1 hydraulic cylinder |

| Limit stop | compressed air connection 6 bar |

| Total connected load | 10.5 kW |

| Floor space | 495 x 152 cm |

| Height | 200 cm |

| Net weight | 7000 kg |

Specifications subject to alterations.

TECHNICAL DATA MultiCut DC 3200

| Type | MultiCut DC 3200 |

| Cutting length | 3210 mm |

| Insertion height | 80 mm |

| Cutting range | 20-470 mm |

| Machine table | positioning drive, 2 ball-screw-assembly |

| Pressure bar | 3 hydraulic cylinders, 2 pressure stages |

| Top knife | brake motor, gearing, crank drive |

| Bottom knife | 1 hydraulic cylinder |

| Limit stop | compressed air connection 6 bar |

| Total connected load | 10.5 kW |

| Floor space | 535 x 152 cm |

| Height | 204 cm |

| Net weight | 7500 kg |

Specifications subject to alterations.

TECHNICAL DATA MultiCut DC 3800

| Type | MultiCut DC 3800 |

| Cutting length | 3810 mm |

| Insertion height | 80 mm |

| Cutting range | 20-470 mm |

| Machine table | positioning drive, 2 ball-screw-assembly |

| Pressure bar | 3 hydraulic cylinders, 2 pressure stages |

| Top knife | brake motor, gearing, crank drive |

| Bottom knife | 1 hydraulic cylinder |

| Limit stop | compressed air connection 6 bar |

| Total connected load | 10.5 kW |

| Floor space | 595 x 152 cm |

| Height | 204 cm |

| Net weight | 8000 kg |

Specifications subject to alterations.

TECHNICAL DATA MultiCut DC 4200

| Type | MultiCut DC 4200 |

| Cutting length | 4210 mm |

| Insertion height | 80 mm |

| Cutting range | 20-470 mm |

| Machine table | positioning drive, 2 ball-screw-assembly |

| Pressure bar | 3 hydraulic cylinders, 2 pressure stages |

| Top knife | brake motor, gearing, crank drive |

| Bottom knife | 1 hydraulic cylinder |

| Limit stop | compressed air connection 6 bar |

| Total connected load | 10.5 kW |

| Floor space | 635 x 152 cm |

| Height | 204 cm |

| Net weight | 9800 kg |

Specifications subject to alterations.